Propeller dynamics identification#

This tutorial outlines how to perform system identification of the propeller/fan dynamics using Telega.

Zubax Robotics maintains a publicly accessible Airscrew and fan parameters spreadsheet with the basic characteristics of some common propellers.

Prerequisites#

Telega-based motor controller.

Motor, unless it is part of an integrated drive.

DC power supply.

Propeller/fan test stand.

GNU/Linux or macOS.

Network interface adapter, such as Zubax Babel.

Yakut CLI tool installed on your PC.

Configure the motor controller#

The motor controller should be able to drive the motor in the ratiometric torque mode. No velocity control mode is needed; indeed, it would be difficult to tune it adequately without knowing the dynamic parameters of the load, which this tutorial is focused on.

This tutorial does not cover the initial configuration of a Telega-based motor controller; for that, refer to other tutorials, such as Yakut CLI tool.

Collect data using the driver script#

The following script will exercise the drive to make the dynamics observable and emit sampled data via stdout as TSV. Run it as specified in the instructions, piping the output into a file.

1#!/usr/bin/env python

2# Author: Pavel Kirienko <pavel.kirienko@zubax.com>

3

4"""

5This script drives the motor in the ratiometric torque mode while varying the setpoint

6to make the dynamic parameters of the load observable.

7It needs PyCyphal to run.

8

9The motor controller shall be configured as follows:

10

11- The feedback topic publication rate should be high, at least 100 Hz.

12 mns.pub_interval_min: 0.005

13

14- The sensor feed from the motor controller shall be timestamped.

15 mns.local_timestamp: true

16

17The measurement feed is printed into stdout (should be redirected to a file).

18Use Dyshlo offline dynamics identification tool to process the data.

19

20The script provides the following topics:

21

22- Readiness command publisher "readiness" of type zubax.service.Readiness.1.

23

24- Ratiometric setpoint publisher "sp_rat" of type zubax.primitive.real16.Vector31.1.

25 This should normally be the ratiometric torque setpoint, although other ratiometric modes can be used as well.

26 All elements are set to the same value.

27

28- Subscriber "fb_dyn" of type zubax.physics.dynamics.DoF3rdTs.1.

29 This is the feedback from the motor controller.

30

31The setpoint range can be adjusted via register "setpoint_rat_lo_hi" of type real32[2].

32

33You can run this script either directly or via Yakut Orchestrator;

34in the latter case, write up roughly the following configuration and execute it as a script:

35

36 #!/usr/bin/env -S yakut -v orc

37 uavcan:

38 pub.readiness.id: 10 # Remove if the readiness subject is not used in your application.

39 pub.sp_rat.id: 24

40 sub.fb_dyn.id: 110

41 $=:

42 - ./dynamics_id_driver.py

43

44Or simply pass the register values via environment variables;

45omit the readiness publisher if the readiness subject is not used in your application:

46

47 UAVCAN__PUB__READINESS__ID=10 UAVCAN__PUB__SP_RAT__ID=24 UAVCAN__SUB__FB_DYN__ID=110 ./dynamics_id_driver.py

48"""

49

50from __future__ import annotations

51import os

52import sys

53import math

54import asyncio

55import logging

56import numpy as np

57import pycyphal.application # pip install pycyphal; export CYPHAL_PATH=~/public_regulated_data_types

58from uavcan.node import GetInfo_1 as GetNodeInfo

59from zubax.physics.dynamics import DoF3rdTs_1 as FeedbackDyn

60from zubax.primitive.real16 import Vector31_1 as Real16_31

61from zubax.service import Readiness_1 as Readiness

62

63_logger = logging.getLogger(__name__)

64

65_OUTPUT_COLUMNS = ["ts_local", "t", "force", "velocity", "acceleration"]

66_COLUMN_SEP = "\t"

67

68

69async def on_feedback(fb: FeedbackDyn, meta: pycyphal.transport.TransferFrom) -> None:

70 print(

71 meta.timestamp.monotonic,

72 fb.timestamp.microsecond * 1e-6,

73 fb.value.force,

74 fb.value.kinematics.base.velocity,

75 fb.value.kinematics.acceleration,

76 sep=_COLUMN_SEP,

77 )

78

79

80async def publish_until(

81 publisher_message_pairs: list[tuple[pycyphal.presentation.Publisher | None, object]],

82 deadline: float,

83 publication_period: float,

84) -> None:

85 get_time = asyncio.get_event_loop().time

86 next_pub_at = get_time()

87 while (now := get_time()) < deadline:

88 for pub, msg in publisher_message_pairs:

89 if pub is not None:

90 pub.publish_soon(msg(now) if callable(msg) else msg)

91 next_pub_at += publication_period

92 if (sleep_duration := next_pub_at - get_time()) > 0:

93 await asyncio.sleep(sleep_duration)

94

95

96async def main() -> None:

97 node = pycyphal.application.make_node(GetNodeInfo.Response(name="com.zubax.telega.dynamics_id_driver"))

98 try:

99 pub_readiness = node.make_publisher(Readiness, "readiness")

100 except pycyphal.application.PortNotConfiguredError:

101 pub_readiness = None

102 pub_sp_rat = node.make_publisher(Real16_31, "sp_rat")

103 sub_fb_dyn = node.make_subscriber(FeedbackDyn, "fb_dyn")

104 sp_rat_low, sp_rat_high = node.registry.setdefault("setpoint_rat_lo_hi", [0.1, 0.9]).floats

105 if not (sp_rat_low < sp_rat_high):

106 raise RuntimeError("Invalid torque range")

107 period = float(node.registry.setdefault("period", 2.0))

108 pattern_duration = float(node.registry.setdefault("pattern_duration", 200.0))

109 init_duration = float(node.registry.setdefault("init_duration", 5.0))

110 setpoint_period = float(node.registry.setdefault("setpoint_period", 0.005))

111 get_time = asyncio.get_event_loop().time

112 try:

113 node.start()

114 _logger.info("Initialization: let the motor run at high power briefly before the pattern starts")

115 await publish_until(

116 [

117 (pub_readiness, Readiness(Readiness.ENGAGED)),

118 (pub_sp_rat, Real16_31([sp_rat_high] * 31)),

119 ],

120 get_time() + init_duration,

121 setpoint_period,

122 )

123 _logger.info("Pattern commenced")

124 while (await sub_fb_dyn.receive_for(0)) is not None:

125 pass # Flush the queue

126 print(*_OUTPUT_COLUMNS, sep=_COLUMN_SEP)

127 sub_fb_dyn.receive_in_background(on_feedback)

128

129 def make_sp_msg(now: float):

130 sp_val = np.interp(math.sin(now / (period / (math.pi * 2))), (-1, 1), (sp_rat_low, sp_rat_high))

131 return Real16_31([sp_val] * 31)

132

133 await publish_until(

134 [

135 (pub_readiness, Readiness(Readiness.ENGAGED)),

136 (pub_sp_rat, make_sp_msg),

137 ],

138 get_time() + pattern_duration,

139 setpoint_period,

140 )

141 finally:

142 if pub_readiness is not None:

143 pub_readiness.close()

144 pub_sp_rat.close()

145 sub_fb_dyn.close()

146 node.close()

147

148

149if __name__ == "__main__":

150 logging.basicConfig(

151 stream=sys.stderr,

152 format="%(asctime)s %(levelname)-5.5s %(name)s: %(message)s\n",

153 level=logging.DEBUG if os.environ.get("VERBOSE", "0").strip() != "0" else logging.INFO,

154 )

155 logging.getLogger("pycyphal").setLevel(logging.INFO) # Do not print debug stuff, it is too verbose.

156 try:

157 asyncio.run(main())

158 except KeyboardInterrupt:

159 pass

160 except Exception as ex:

161 _logger.debug("Unhandled exception", exc_info=True)

162 print(f"Error: {str(ex) or repr(ex)}", file=sys.stderr)

163 sys.exit(1)

Perform offline regression#

The file recorded in the previous step will contain a large time series dataset that will need to be fed into the regressor script provided below. If the identification is performed correctly, the \(c_1\) value found by the regressor will be very small; a large \(c_1\) may indicate either a problem with the drive itself (high friction) or a controller tuning problem.

1#!/usr/bin/env python3

2# Pavel Kirienko <pavel.kirienko@zubax.com>

3

4"""

5This script performs offline identification of the dynamic parameters of the mechanical load

6attached to the motor based on the load's response to force/torque variation.

7It needs to be fed a timestamped TSV stream via stdin containing columns named as follows

8(extra columns are allowed and will be ignored):

9

10- t [second]

11- force [newton] or [newton*meter]

12- velocity [meter/second] or [radian/second]

13- acceleration [meter/second^2] or [radian/second^2]

14

15The means of collecting such data lie outside the scope of this script.

16Normally it would be performed with the help of some external utility that would exercise the drive

17with a specified force/torque profile and record the response.

18The profile is normally sinusoidal, but ultimately it is not critical.

19

20The identified dynamic parameters are printed as YAML, which are:

21

22- Load (rotational) mass m.

23

24- Linear friction coefficient c1, defined as, translational and rotational:

25

26 F = c1 * v

27 Q = c1 * omega

28

29- Quadratic drag coefficient c2, defined as, translational and rotational:

30

31 F = c2 * v^2

32 Q = c2 * omega^2

33

34The aerodynamic drag can be trivially deduced from c2 if the fluid density and the

35cross-sectional area of the load are known.

36The standard aerodynamic drag equation is:

37

38 F = v^2 * (0.5 * rho * A * C_drag)

39

40Where rho is the fluid density, A is the cross-sectional area, and C_drag is the drag coefficient.

41Substitute:

42

43 c2 = 0.5 * rho * A * C_drag

44 C_drag = c2 / (0.5 * rho * A)

45

46The equivalent cross-sectional area may not be known,

47in which case it may be convenient to use the product of A and the drag coefficient,

48or assume A = 1 (which is common):

49

50 A * C_drag = c2 / (0.5 * rho)

51

52The above equations are valid for translational motion.

53In the case of a fan or propeller, the equation of interest is that of the torque Q:

54

55 Q = C_torque * rho * D^5 * n^2

56

57Where C_torque is the rotational counterpart of C_drag called the propeller's torque coefficient,

58n is the angular velocity in hertz, and D is the propeller/fan diameter.

59The choice of hertz for the angular velocity in the torque equation is in line with

60the commonly accepted conventions in the propeller theory,

61but this is inconsistent with the normal use of radian per second for angular velocity elsewhere.

62Hence, here is the same torque formula with the angular velocity omega expressed in radian per second:

63

64 Q = C_torque * rho * D^5 * (omega / (2 * pi))^2

65

66 Q = C_torque * rho * D^5 * (1 / (4 * pi^2)) * omega^2

67 |_______________________________________|

68 c2

69

70Express C_torque in terms of c2:

71

72 c2 = C_torque * rho * D^5 * (1 / (4 * pi^2))

73 C_torque = 4 * pi^2 * c2 / (rho * D^5)

74

75References:

76

77- 16.Unified: Thermodynamics and Propulsion, Prof. Z. S. Spakovszky

78 https://web.mit.edu/16.unified/www/FALL/thermodynamics/notes/node86.html

79

80- 2.016 Hydrodynamics, Prof. A.H. Techet

81 http://web.mit.edu/2.016/www/handouts/2005Reading10.pdf

82"""

83

84import os

85import sys

86import math

87import logging

88import argparse

89import numpy as np

90import pandas

91import pandas as pd

92import scipy.optimize

93

94

95_logger = logging.getLogger(__name__.replace("__", ""))

96

97

98def _predict_acceleration(velocity, force, mass, *, c1, c2):

99 drag = -(np.copysign(velocity**2, velocity) * c2 + velocity * c1)

100 acc = (force + drag) / mass

101 return acc

102

103

104def _compute_loss(df: pd.DataFrame, mass, *, c1, c2) -> float:

105 prediction = _predict_acceleration(

106 df.velocity,

107 df.force,

108 mass,

109 c1=c1,

110 c2=c2,

111 )

112 divergence = df.acceleration - prediction

113 return float(np.sum(divergence**2))

114

115

116def main() -> None:

117 arp = argparse.ArgumentParser(description=__doc__, formatter_class=argparse.RawTextHelpFormatter)

118 arp.add_argument("--no-plot", action="store_true", help="Do not plot the results; removes the dependency on plotly")

119 arp.add_argument(

120 "--mass-min", type=float, default=1e-9, help="Min (rotational) mass in [kg] or [kg*m^2]; default=%(default)s"

121 )

122 arp.add_argument(

123 "--mass-max", type=float, default=1e3, help="Max (rotational) mass in [kg] or [kg*m^2]; default=%(default)s"

124 )

125 arp.add_argument(

126 "--c1-max", type=float, default=0, help="Max c1 coeff in [N*s/m] or [N*m*s/rad]; default=%(default)s"

127 )

128 arp.add_argument(

129 "--c2-max", type=float, default=1e2, help="Max c2 coeff in [N*s^2/m^2] or [N*m*s^2/rad^2]; default=%(default)s"

130 )

131 args = arp.parse_args()

132

133 df = pd.read_table(sys.stdin)

134 _logger.info("Loaded %d samples", len(df))

135 max_valid_index = min(df.apply(lambda series: series.last_valid_index()))

136 min_valid_index = 0

137 for idx in range(max_valid_index, -1, -1):

138 if not np.alltrue(np.isfinite(df.iloc[idx])):

139 break

140 min_valid_index = idx

141 # Cut off the beginning of the data to minimize boundary effects.

142 min_valid_index += int(0.1 * (max_valid_index - min_valid_index))

143 df = df.iloc[min_valid_index : max_valid_index + 1]

144 _logger.info(

145 "%d samples in %d:%d after normalization:\n%s\n%s\n",

146 len(df),

147 min_valid_index,

148 max_valid_index,

149 df,

150 df.describe(),

151 )

152

153 def fun(x):

154 loss = _compute_loss(df, mass=x[0], c1=x[1], c2=x[2])

155 if not math.isfinite(loss):

156 raise RuntimeError(f"Numerical failure at {x=}")

157 return loss

158

159 mass_bounds = (float(args.mass_min), float(args.mass_max))

160 c1_bounds = (0.0, float(args.c1_max))

161 c2_bounds = (0.0, float(args.c2_max))

162 arg_initial = np.array([1.0, 0.0, 0.0])

163 # https://stackoverflow.com/questions/34663539

164 res = scipy.optimize.minimize(

165 fun,

166 arg_initial,

167 bounds=(mass_bounds, c1_bounds, c2_bounds),

168 options=dict( # https://stackoverflow.com/questions/34663539

169 eps=1e-9,

170 ftol=1e-15, # Tolerance override is quite necessary.

171 gtol=1e-15,

172 ),

173 )

174 _logger.info("Optimization result:\n%s\n", res)

175 est_mass, est_c1, est_c2 = res.x

176 print(f"mass:{est_mass:12.6} # [kg] | [kg*m^2]")

177 print(f"c1: {est_c1 :12.6} # [N*s/m] | [N*m*s/rad]")

178 print(f"c2: {est_c2 :12.6} # [N*s^2/m^2] | [N*m*s^2/rad^2]")

179 _logger.info(

180 "FYI, estimated propeller torque coefficient for D=1[meter] in standard Earth atmosphere: %s",

181 4 * math.pi**2 * est_c2 / 1.225,

182 )

183

184 if not args.no_plot:

185 _plot(df, est_mass=est_mass, est_c1=est_c1, est_c2=est_c2)

186

187

188def _plot(df: pandas.DataFrame, *, est_mass: float, est_c1: float, est_c2: float) -> None:

189 try:

190 import plotly.subplots

191 import plotly.graph_objects

192 except ImportError:

193 _logger.warning("Skipping plot due to missing plotly dependency")

194 return

195 specs = [

196 [{"secondary_y": True}],

197 ]

198 fig = plotly.subplots.make_subplots(rows=len(specs), cols=len(specs[0]), shared_xaxes=True, specs=specs)

199 fig.add_trace(

200 plotly.graph_objects.Scatter(

201 x=df.t,

202 y=df.force,

203 mode="lines",

204 name="F",

205 ),

206 secondary_y=True,

207 )

208 fig.add_trace(

209 plotly.graph_objects.Scatter(

210 x=df.t,

211 y=df.acceleration,

212 mode="markers",

213 name="a",

214 ),

215 )

216 fig.add_trace(

217 plotly.graph_objects.Scatter(

218 x=df.t,

219 y=_predict_acceleration(

220 df.velocity,

221 df.force,

222 est_mass,

223 c2=est_c2,

224 c1=est_c1,

225 ),

226 mode="lines",

227 name="a'",

228 ),

229 )

230 fig.update_layout(height=800, hovermode="x")

231 try:

232 fig.show()

233 except Exception as e:

234 _logger.exception("Failed to show plot: %s", e)

235

236

237if __name__ == "__main__":

238 logging.basicConfig(

239 stream=sys.stderr,

240 format="%(asctime)s %(levelname)-5.5s %(name)s: %(message)s",

241 level=logging.DEBUG if os.environ.get("VERBOSE", "0").strip() != "0" else logging.INFO,

242 )

243 try:

244 main()

245 except KeyboardInterrupt:

246 pass

247 except Exception as ex:

248 _logger.exception("Error: %s", ex, exc_info=True)

249 sys.exit(1)

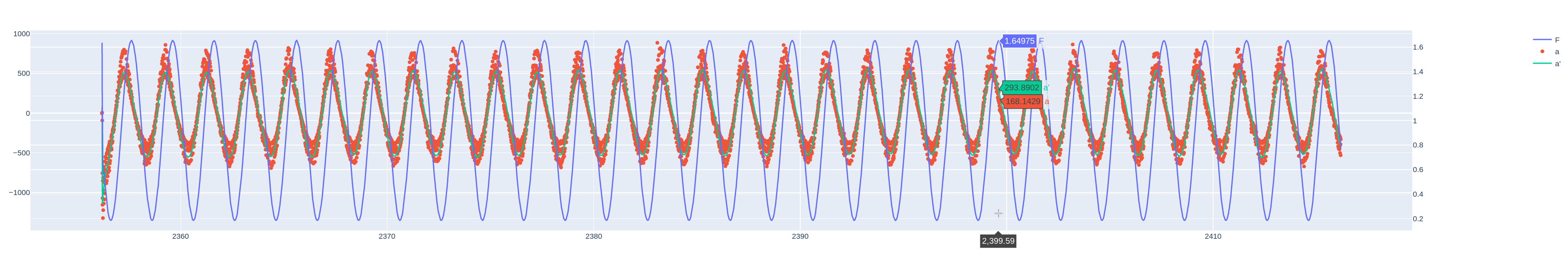

The following plot visualizes the collected data points and the fitted parameters:

A real-time regressor is available for applications where runtime dynamics identification is required. Please reach out to Zubax Robotics for additional information.

Application notes#

The parameters found by this procedure can be used with model-based controllers, such as the incremental nonlinear dynamics inversion velocity controller.

The parameters can also be used for sizing the drivetrain for a given application. As the propeller/fan torque is a function of its torque coefficient and its angular velocity, one can predict the torque at the shaft and the angular velocity for the given lift; next, knowing the motor parameters, the motor controller, DC link, and battery requirements can be deduced. For more information on this, refer to the Drive power transfer equation.

The torque and thrust coefficients are strongly dependent on the airspeed. For the dynamics identification to be valid for forward flight, the test should be performed in a wind tunnel.